Produce hydrogen for refinery hydrotreating and hydrocracking or other refinery, petrochemical and industrial applications.

Feed: Natural gas, refinery offgas, LPG/butane, light naphtha and multiple feedstock.

Product: High-purity hydrogen (>99.9%). CO, CO2 and/or electricity may also be produced separately for byproduct credit.

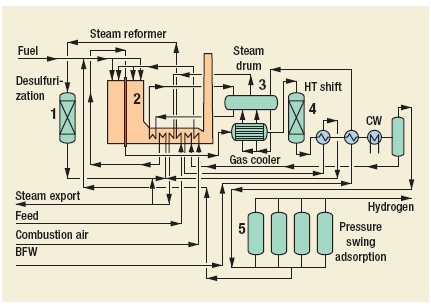

The feedstock (natural gas, for example) is desulfurized (1), mixed with steam and converted to synthesis gas in the reformer (2) over nickel catalysts at 20 to 50 bar pressure and temperatures of 800°C to 950°C.

The Uhde steam reformer is a top-fired reformer, which has tubes made of centrifugally cast alloy steel and a proprietary “cold” outlet manifold system to enhance reliability. Subsequent high-pressure steam generation (3) and super heating permit maximum process heat exploitation to achieve an optimized energy-efficient process.

The carbon monoxide (CO) shift occurs in a single stage, adiabatic high-temperature reactor (4). Pressure swing adsorption (5) is a well-established purification step to obtain high-purity hydrogen (99.9 % and higher).

The Uhde reformer design with the unique proprietary cold outlet manifold system enables construction

and operation of world-scale reformers with hydrogen capacities to 290,000 Nm3/h.

Economics: Typical consumption figures (feed and fuel) range between 150 and 175 GJ/metric ton of hydrogen, depending on the individual plant concept.

Licensor: Uhde GmbH, Dortmund, Germany