Wet-scrubbing process purifies Claus tail gas for total sulfur recovery ranging from 99.8% to 99.9+%.

Description: The optimum Claus tail-gas treatment converts sulfur species to H2S and recovers it in a wetscrubbing process. The Lurgi tail-gas treatment process (LTGT) is an amine treating system with generic MDEA solvent, structured packing and plate heat exchangers when possible. This process enables using smaller diameter columns, plot size, worldwide treating solution availability, proven technology and high selectivity. Installing smaller equipment lowers total

investment costs.

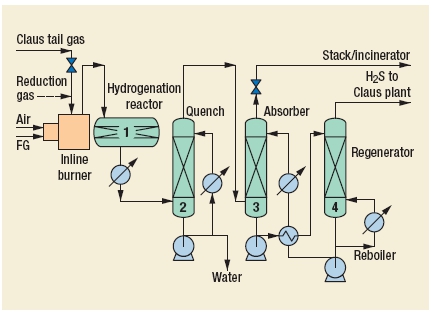

Different sulfur species from the incoming Claus tail gas are converted (1) to H2S. Process water formed by the Claus reaction is removed in a direct cooler (2), and H2S is expunged by MDEA solution in an absorber column (3). The amine solution is regenerated in a steamheated stripper column (4) and produces a H2S gas stream that is recycled back to the Claus section. Due to hydrogenation in the tail-gas treatment, both acid gases—H2S and CO2—are produced and routed to the absorber column.

Tertiary amines like MDEA, which are used in the LTGT, have the ability to selectively absorb H2S due to chemical structure and do not co-absorb CO2. Primary (MEA) and secondary amines (DEA) will absorb H2S along with most of the CO2. In tertiary amine solutions, CO2 can only be absorbed by an indirect acid/base reaction forming bicarbonates; this is a very slow reaction.

Economics: Investment amounts are approximately 85–95% of the Claus unit cost. Using a common regeneration along with the upstream amine unit, investments are approximately 65–75% of the Claus unit cost.

Licensor: Lurgi Oel-Gas-Chemie GmbH