Recovery via extraction of high-purity C6–C9 aromatics from pyrolysis gasoline, reformate, coke oven light oil and kerosine fractions.

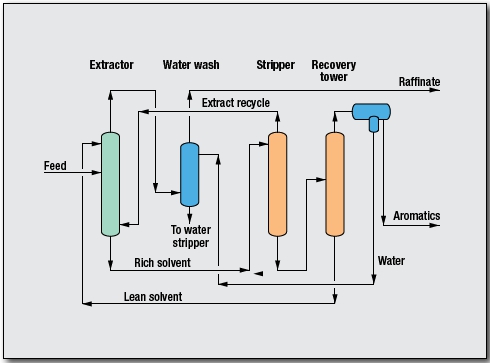

Hydrocarbon feed is pumped to the liquid-liquid extraction column (1) where the aromatics are dissolved selectively in the sulfolane water-based solvent and separated from the insoluble non-aromatics (paraffins, olefins and naphthenes). The non-aromatic raffinate phase exits at the top of the column and is sent to the wash tower (2). The wash tower recovers dissolved and entrained sulfolane by water extraction and the raffinate is sent to storage. Water containing sulfolane is sent to the water stripper.

The solvent phase leaving the extractor contains aromatics and small amounts of non-aromatics. The latter are removed in the stripper (3) and recycled to the extraction column. The aromatic-enriched solvent is pumped from the stripper to the recovery tower (4) where the aromatics are vacuum distilled from the solvent and sent to downstream clay treatment and distillation. Meanwhile, the solvent is returned to the extractor and the process repeats itself.

Yields: Overall aromatics’ recoveries are > 99% while solvent losses are extremely small—less than 0.006 lb/bbl of feed.

Licensor: Axens